Atachi Systems provides manufacturing companies with a seamless, cloud-based Manufacturing Execution System

– NGIMES. NGIMES is the Next Generation

Pharmaceutical Manufacturing

NGIMES is highly configurable Manufacturing Execution System (MES) for Pharmaceutical Manufacturing. NGIMES can be quickly deployed for the bulk drugs, API, formulation and packaging sections of the pharmaceutical manufacturing companies.

Medical Devices and Diagnostics

Cloud-based mes (NGIMES) for MD&D comes with electronic signatures, electronic device history records and other FDA-compliant features to help streamline quality product development.

Electronics Manufacturing

Our MES solution for electronics manufacturing is designed for rapid response to the critical and competitive demands of short product life cycles.

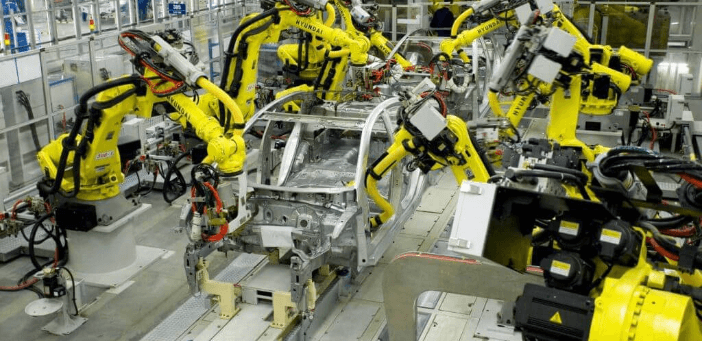

Automotive Manufacturing

Automotive industry has been swamped with several product recalls almost every few months. The top automotive manufacturers couldn’t become an exception for the product recalls. NGIMES provides the real-time insights into the manufacturing operations to avoid the product recalls and CAPA (Corrective and Preventative actions).

Automotive Manufacturing

Glass Manufacturing is a fast moving highly automated production environment where the operational parameters, equipment defects need to be captured faster than the product movement so that production wastage can be reduced. Precision in inspecting the defective products is a key to improve the profitability.

NGIMES | MES for Industry 4.0 | MES with IIOT | Integrated MES | Next Generation MES

Most of the MES systems in today’s MES market are legacy on-premise systems that need lot of maintenance and upgrade costs and time. No doubt couple of these legacy MES systems were state-of-the art MES systems at the time of building 20 years back. Even though few of these systems changed their underlying platforms but still struggling to accommodate the today’s business needs of speed and agility. Having deployed for the last 10+ years these legacy MES or On-premise MES systems, Atachi has built the cloud-based MES or cloud MES leveraging the SAP Cloud Platform technologies. Atachi NGIMES is the truly Next Generation MES bringing the manufacturing companies to Industry 4.0 standard. NGIMES helps in realizing the goals of Manufacturing Digitalization | Manufacturing Digitization.

NGIMES – The Next Generation Integrated MES in the cloud powered with SAP HANA platform for Manufacturing companies. A cloud-based MES: NGIMES is quick to deploy and minimizes deployment, maintenance and licenses costs so you can maximize profits.

Focus on business, instead of IT dependencies.

Cloud MES| Cloud-based MES| Cloud MES for Discrete Manufacturing| Cloud MES for Process Manufacturing|MES for SMB| MES for companies of all sizes

NGIMES (the next generation integrated mes in the cloud) empowers discrete and process manufacturing industries with complete integrated solution(s). With traditional MES solutions, you pay additional fees for mobility, support, licenses and real-time report features. With NGIMES, all are included in the package.

Latest Blogs

-

Like Use your QMS to keep your company’s policies and procedures aligned with the launching and scaling of your products. The digital age has changed the way we act, think and communicate. Yet, in so many cases the world of quality and compliance is still managed and indeed hampered by manual, paper-based systems. Quality management…

-

Like Continuous Change Requires Continuous Innovation: Today’s pharmaceutical manufacturers and distributors are witnessing a paradigm shift in consumer behavior, market dynamics, margins, and increased compliance mandates brought about by the influx of modern technology. Efficient business processes, Centralized management, Quick decision-making, and Clear analytics have become essential for any business to grow in the modern-day…

-

Like ERP knows the ‘why’ of things, MES knows the ‘how to’. While MES Sofware solutions primarily support business decisions, the ERP supports the operational ones. Features of MES software solution: Collect process and machine data from data silos Automatically create notifications and logs for issues Enforce product specifications and business rules Defect tracking and…

-

Like Want to Make Decisions, Complete Projects, and work with Maximum Efficiency? – The Right ECM System will help you. It is a systematic approach to managing content throughout its lifecycle. It enables unstructured information — such as Word documents, PDFs, emails, and scanned images — to be securely stored and made accessible to authorized…

-

Like Gurmeet Singh has made a significant contribution to the pharmaceutical industry. He comes with over 30 years of unique, innovative, and multifaceted experience in the industry often hailed as straight-jacketed with no great change in operating practices. He established an enviable network of specialists spanning the Americas, Europe, and the versatile Indian market. He…

-

Like Pharmaceutical companies are under pressure to achieve better control of their production processes and to increase transparency and traceability. This is where MES comes into play. Companies can now capture real-time data and make it available across multiple sites. By connecting equipment to information systems and operator interfaces, it is possible to regulate every…

-

Like What Is MES Software? Some Important Benefits and Details The Hidden Factory – Not To Be Ignored: The Hidden Factory refers to parts of a manufacturing process that decrease the quality or efficiency of operation -the mistakes, the rework, the waste – all the things that are kept hidden from the eyes of the…

-

Like Atachi Systems Pledges Free Mes Software For 50 Small Medical Devices & Diagnostics, Pharma And Life Sciences Manufacturers For 1 Year. Atachi Systems Pledges Free MES software for 50 Small Medical Devices & Diagnostics, Pharma and Life Sciences Manufacturers for 1 year. Atachi Systems would like to join the community in helping the small…

-

Like NGIMES is one of the top 10 Global MES solutions for Pharma companies in the world. – Pharma MES SWOT analysis by global research firms. Atachi Systems provides manufacturing companies with o seamless, cloud-based manufacturing Execution System – NGIMES. NGIMES is the Next Generation Integrated Manufacturing Execution Systems. Atachi Systems’ experience in deploying MES…